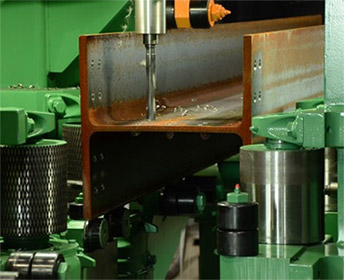

The PCD-1100/3B Beam Drill Line

This CNC drill line was our first automated drill line added to Redd Iron’s arsenal in 2008. Designed to apply high steel (morse taper) drill tooling with a mist coolant sytem delivered directly through the bit for long tool life. From square\rectangular tubes to channel, beams and flat plate this machine will drill it all quickly and accurately. Three spindles give you drilling continuously on all axis at this same time for a speed that will yield 50-75 tons of drilled product per week.

Roller Measurment

The rolling measurement system on this machine allows for the imperfections in structural steel to product accuracy within 1/32” and a strong in feed drive roller mechanism to push 20,000lbs members. By applying 2 encoders simultaneously the accuracy is reliable with a failsafe system that ensures quality measurements every time

Layout/Part Marking

Layout marking and carbide scribing are critical to accuracy, and reliability in today’s modern fabricaton shops. The PCD-1100/3B offers a unique stationary carbide scribing station located on the top flange of a profile, and also performs streamlined layout marking via each of the available drill spindles